How to determine if your manufacturing process is automation ready and what to do if it’s not.

“We need to automate this process” is a phrase we hear quite regularly from MedTech manufacturers who are facing increasing pressure to improve quality, reduce costs and scale their production. Manual assembly lines that once met demand are now bottlenecks. Quality issues that were once manageable are becoming critical and labour costs/workforce availability concerns are on the increase.

Automation seems like the obvious solution. But here’s what 20+ years of designing custom automation systems has taught us: not every process is ready for automation, and that’s perfectly okay.

The Hidden Cost of “Not Ready”

Last year, we worked with a medical device manufacturer who needed immediate automation. Their manual assembly process was causing quality issues and they were under pressure to increase throughput.

The problem? Their process documentation was incomplete, product specifications kept changing, and they hadn’t defined clear success metrics. Six months later, after investing significant time and resources, the project stalled.

The good news? Once the time was taken to properly prepare, the automation project became one of our most successful implementations, delivering a 200% throughput increase and virtually eliminating quality defects.

What Makes a Process “Automation Ready”?

With over 20 years experience of working on MedTech automation projects, we’ve identified the essential readiness factors. Master these, and your automation project has an excellent chance of success. Miss them, and you’re setting yourself up for delays, cost overruns and frustration.

-

- Build A Foundation (Documentation & Specifications)

Before any engineering work begins, you need a clear understanding of your current process. This means detailed process flows, comprehensive product specifications, and realistic performance targets. Think of it this way, if you can’t explain your process clearly to a human, how can you expect to program a machine to execute it?

- Build A Foundation (Documentation & Specifications)

-

- Define Your Framework (Requirements & Environment)

Every successful automation project requires clear boundaries. What level of automation do you actually need? What are your space constraints? What’s your realistic timeline? These aren’t “nice to know” details, they’re essential for your projects success.

- Define Your Framework (Requirements & Environment)

-

- Set Up A Support System (People & Processes)

The best automation systems fail without proper support structures. Who will manage the project internally? How will the system be maintained? What happens when issues arise? These human factors often determine long-term success more than technical specifications.

- Set Up A Support System (People & Processes)

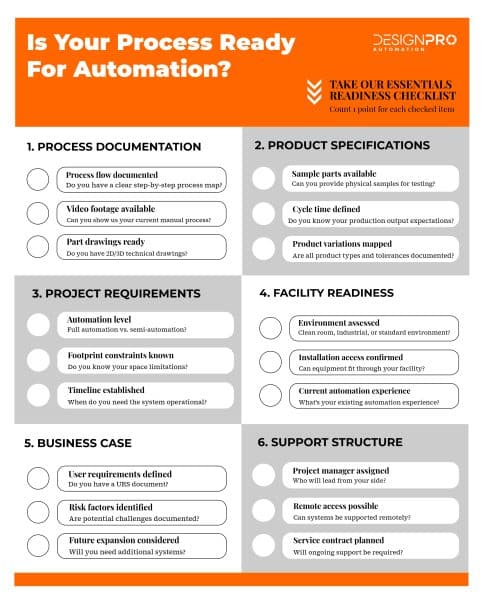

Your Automation Readiness Assessment

We’ve condensed our project evaluation process into a comprehensive checklist that covers all critical readiness factors. Use it to honestly assess where you stand and identify areas needing attention before moving forward.

Interpreting Your Results

15-18 items checked: You’re well-prepared for automation. Your documentation is solid, requirements are clear, and support structures are in place. Time to start evaluating automation partners and getting detailed proposals.

10-14 items checked: You have a good foundation but need to address some gaps first. Focus on completing documentation, finalising requirements and securing internal resources before proceeding.

Less than 10 items checked: Don’t worry – you’re not behind, you’re just getting started. Invest time in process documentation and requirement definition. Consider bringing in automation consultants early to help with planning.

Ready to Take the Next Step?

Automation readiness isn’t about being perfect, it’s about being prepared. Whether you’re just starting to explore automation or ready to move forward immediately, understanding your current position is the first step toward success. Download our Automation Readiness Checklist and start your assessment today.

Have questions about your specific situation? Our team has evaluated hundreds of automation opportunities across the MedTech industry. We’re happy to discuss your process and help you determine the best path forward.

Conor Doyle, cdoyle@designproautomation.com | Patrick Downes, pdownes@designproautomation.com

DesignPro Automation specialises in custom automation solutions for the MedTech industry. With over 20 years of experience, we help manufacturers transform manual processes into efficient, reliable automated systems. Contact us at sales@designproautomation.com or +353 (0)69 63842 to discuss your automation needs.