As a manufacturer, reliable and consistent quality control is of the utmost importance. Whether you need to incrementally track progress on an assembly machine or an entire system dedicated to one specific critical test, we can design and custom build an automated testing and inspection machine to ensure your product passes the highest quality standards.

Quality Control

Whether you need to track the status or progress on an assembly machine or an entire system dedicated to one specific critical test, we have designed and custom-built automated testing and inspection equipment to ensure your product passes quality standards.

Tracking & Data Logging

We have used track and trace products such as RFID and barcode technologies, Also using critical process parameters data and product tracing, a full product history is created, this allows us to complete traceability and regulatory compliance.

Testing

We understand that every critical process completed on a product assembly needs validation so we recommend and identify essential areas for testing during our design phase along with our customer’s briefs.

Test & Inspection systems we have integrated include:

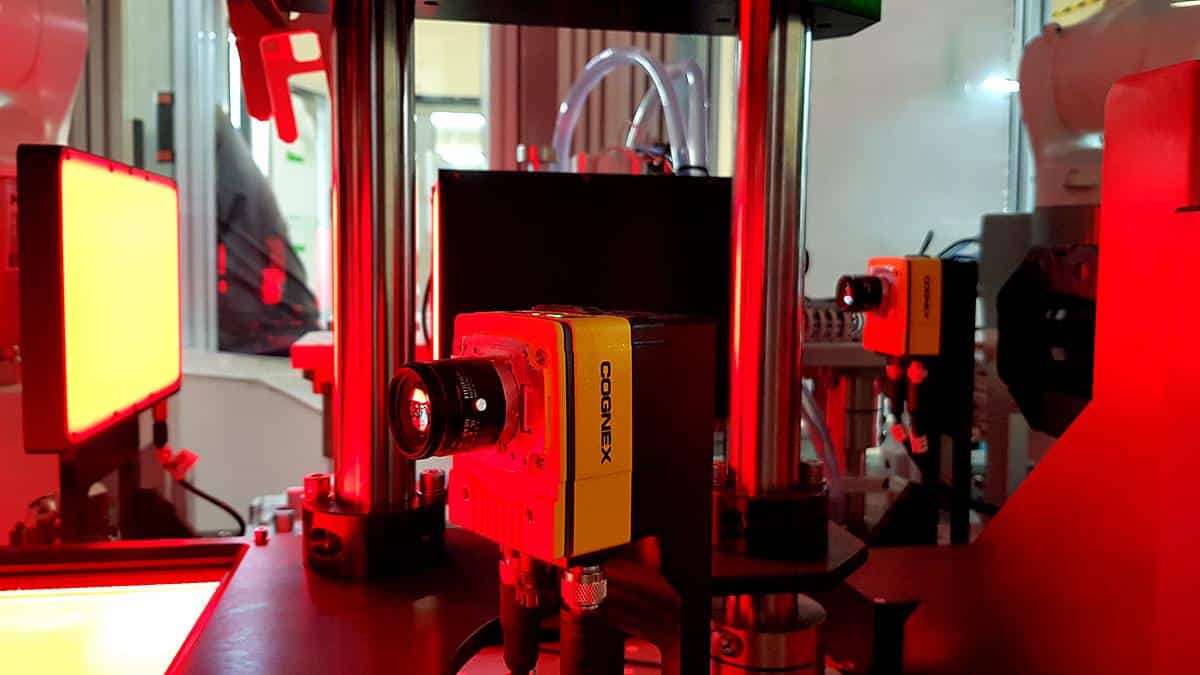

Vision Inspection

Vision systems are used for appearance inspection, positioning, dimensional measurement, presence, text and 1D/2D Bar code inspection. Vision sensors are used for Poka-Yoke and inspection such as edge presence, pitch, diameter, width/height, edge pixels, area, and shape detection.

Electrical

We offer EOL testing and PCB functional testing including; current, voltage, resistance, capacitive testing, and frequency measurements (all AC or DC, with hysteresis measurements and calculation). The process also gathers crucial data on product quality.

Leak & Pressure Decay

This process is used to detect a leak in products where seal integrity is of the utmost importance. The process involves the following stages:

- Product is filled/pulled with either pressure or vacuum.

- Stabilising phase allows the pressure/vacuum to stabilize within the product.

- Monitored and measured against a set value for a pass or fail.

Torque, Force & Distance Testing

We have designed and incorporated force feedback systems in servo drives and linear actuators for high precision placements / set forces and torquing for various applications. Using upper and lower limit thresholds on the forces will ensure consistent, calibrated and accurate movements.

Data Logging & Product Tracking

Depending on the site server, we have outputted critical test data into a customer’s SQL database. This data can be stored local on a machine PC or sent to a network server position using software. We use this to eliminate the possibly of losing data on the PLC memory in the event of a system failure and to record critical data such as overall Equipment Effectiveness (OEE). Our machines can track the product locally between the stations and store the data in memory. Once complete, the critical parameters (UDT) can be retrieved by the site database via software applicable to the PLC type. This means all finished and tested product information will be stored externally from the system (Database). We can create a UDT (user defined structure) with critical parameters data which will be passed to the customers transaction manager.