The Impact of Vision Systems in Medical Device Manufacturing

Machine vision systems are driving significant advancements in manufacturing, enabling companies to achieve higher levels of efficiency, quality, and flexibility. By leveraging the latest technologies and best practices, manufacturers can harness the full potential of vision systems to stay competitive in today’s fast-paced and dynamic market.

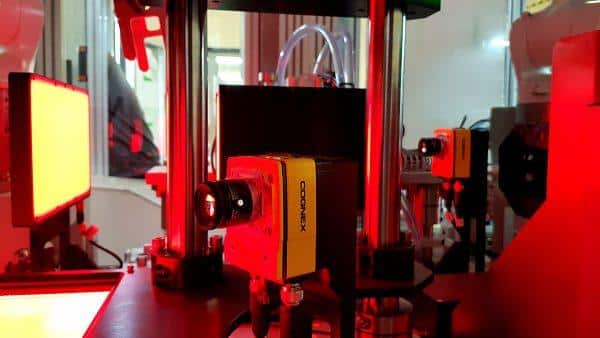

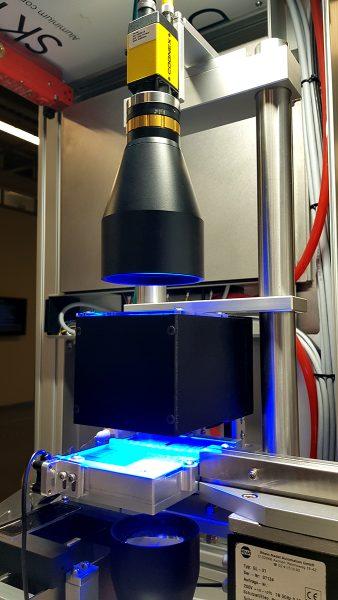

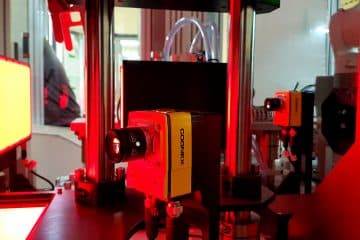

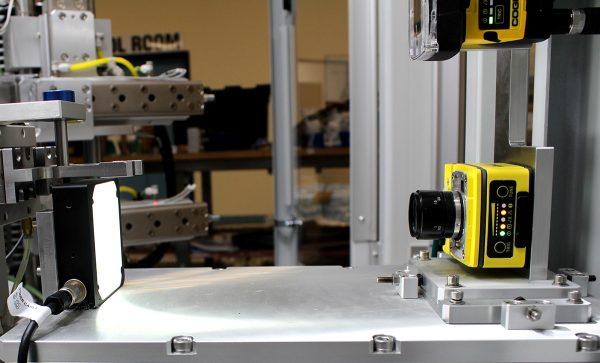

Vision systems have become an indispensable tool for modern manufacturers, particularly in the medical device sector. These systems, powered by sophisticated algorithms and high-resolution cameras, have gone beyond their traditional roles to become the backbone of production lines worldwide.

Unmatched Precision and Accuracy

So, what exactly is driving this surge in adoption, and how are vision systems reshaping the landscape of medical device manufacturing?

First and foremost, vision systems offer unparalleled levels of precision and accuracy. In an industry where even the slightest deviation can have significant repercussions, the ability to inspect and verify components with microscopic detail is nothing short of revolutionary.

From detecting imperfections in intricate components to ensuring the precise placement of vital components, vision systems provide manufacturers with the assurance they need to maintain the highest standards of quality.

Boosting Efficiency and Productivity

Moreover, vision systems are not just about quality control; they are about efficiency and productivity. By automating repetitive tasks that were once performed manually, these systems can drastically reduce production times and minimise the risk of human error.

Whether it’s inspecting thousands of components per minute or guiding robotic arms with pinpoint accuracy, vision systems are redefining the limits of what is possible on the factory floor.

Driving Innovation and Adaptability

But perhaps the most significant impact of vision systems lies in their ability to foster innovation and adaptability. With the advent of technologies such as sensor integration and IO-Link connectivity, manufacturers now have the tools to create dynamic and responsive production environments.

By seamlessly integrating vision systems into existing workflows, companies can quickly adapt to changing market demands and scale their operations with ease.

Advancing Research and Development

Furthermore, vision systems are driving advancements in research and development, enabling manufacturers to push the boundaries of what is achievable. From exploring new materials and manufacturing techniques to refining product designs, these systems are empowering companies to stay at the forefront of innovation and deliver next-generation solutions to patients around the world.

Embrace The Future

Vision systems are opening up an array of endless possibilities for the medical device manufacturing industry. By harnessing the power of these advanced technologies, companies can achieve higher levels of efficiency, quality, and flexibility than ever before. As the pace of innovation continues to accelerate, vision systems will undoubtedly play a central role in shaping the future of medical device manufacturing for years to come.

Do you have an automation project you’d like advice on?