We have developed a wide range of marking and labelling solutions to support the increasing demand for product customisation and traceability. Automated laser marking is an effective solution to automated batch identification. It has a clear advantage over other marking systems when it comes to identifying medical & industrial parts. Ideal for metals & plastics has a high-resolution finish, is programmable, and does not require ink or paint.

Our integrated systems have the ability to mark or indicate data on a product (bar codes, 1D and 2D matrix codes, time stamps, weight, batch number, etc). Accommodating a variety of different shapes and sizes, our marking/cutting processes can produce a high degree of repeat accuracy, guaranteeing short cycle times.

Labelling/Printing

Partnering with leading labelling/printing providers to integrate systems into our equipment, from cleanroom class standalone cells to production lines.

Laser Marking

Advanced industrial laser marking solutions to ensure accuracy and repeatability. Experienced with metal and plastic components.

Laser Cutting/Extraction

Experienced in laser cutting medical grade plastic in cleanroom class equipment to various shaped products and high-quality finishes while maintaining accuracy on the lasered edge.

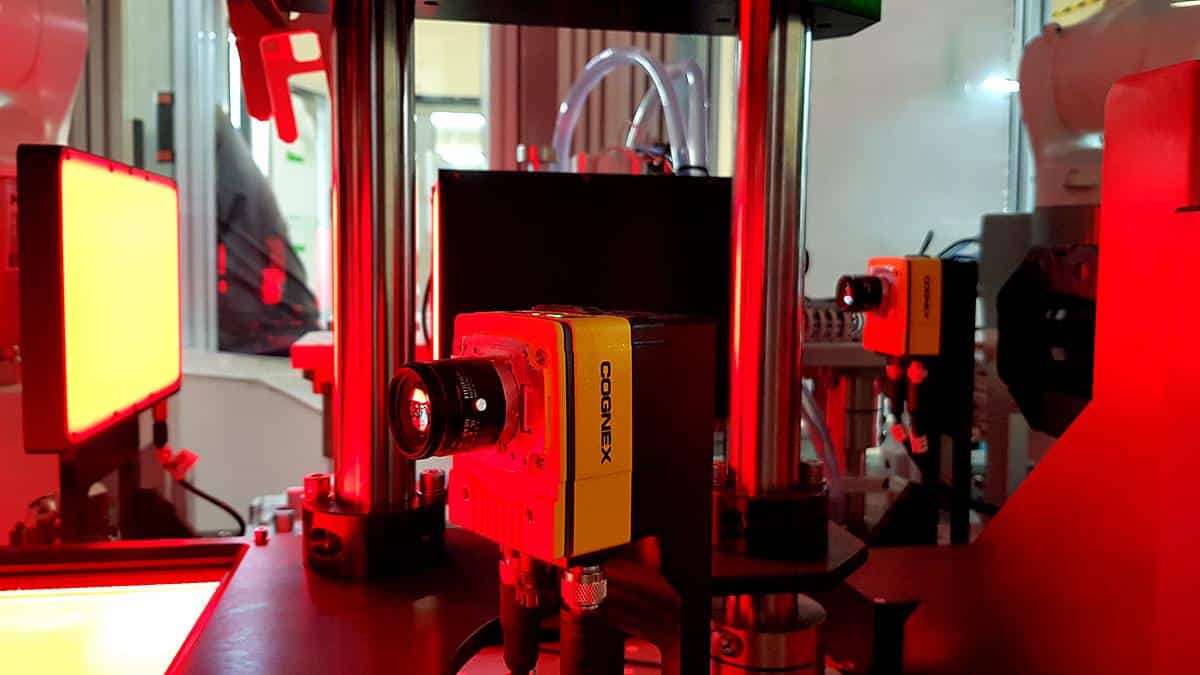

Product Marking/Cutting systems we have integrated include:

Laser Marking

Utilizing Keyence and Trumpf (fibre, C02 & Hybrid) laser marking systems, we have marked various medical and automotive plastics and metal parts with texts, symbols, matrix codes etc.

Laser Cutting

Laser cutting medical-grade flexible film using fibre lasers. Integrated monitored localised extraction systems into cutting areas. Performed thermal heat airflow simulation to determine our volume and direction of flow. Performing proof of concept with our laser suppliers we were able to determine the correct power outage and feed rates for seamless cutting.

Laser Enclosure Class 4

We have developed fully fabricated powder-coated steel frames, with class 4 laser glass viewing windows to house our lasers systems. All our enclosures are CE marked and category 4 safety rated using safety solenoid interlock and monitoring systems within the enclosure. Localized extraction systems with self-monitoring systems provide the required extraction of emitted gases from the cutting process.

Inkjet Marking

We used multi-head Inkjet coders for a production line on medical parts to provide high contrast and high-performance marking. They used an automatic head cleaning system that required minimal attention and provides high-quality coding including a range of texts, logos, 1D and 2D barcodes for the customer’s traceability.

Print & Apply Labelling Systems

Experienced in integration of Print & Apply Systems into our equipment for industrial solutions, and cleanroom environments with high and low production volumes. label positioning includes edge, rotation round product, face and complex geometry placements.