We offer a wide variety of solutions to suit any specific feeder system requirements. Depending on the particular product this can be achieved through a customised or standardised design or by collaborating with one of our specialised partners who have the ability to manufacture high speed, high volume feeding systems with optimum handling and reliability.

Our systems will feed and orientate your products carefully, guaranteeing a consistent and accurate flow of components into your production line.

Integration

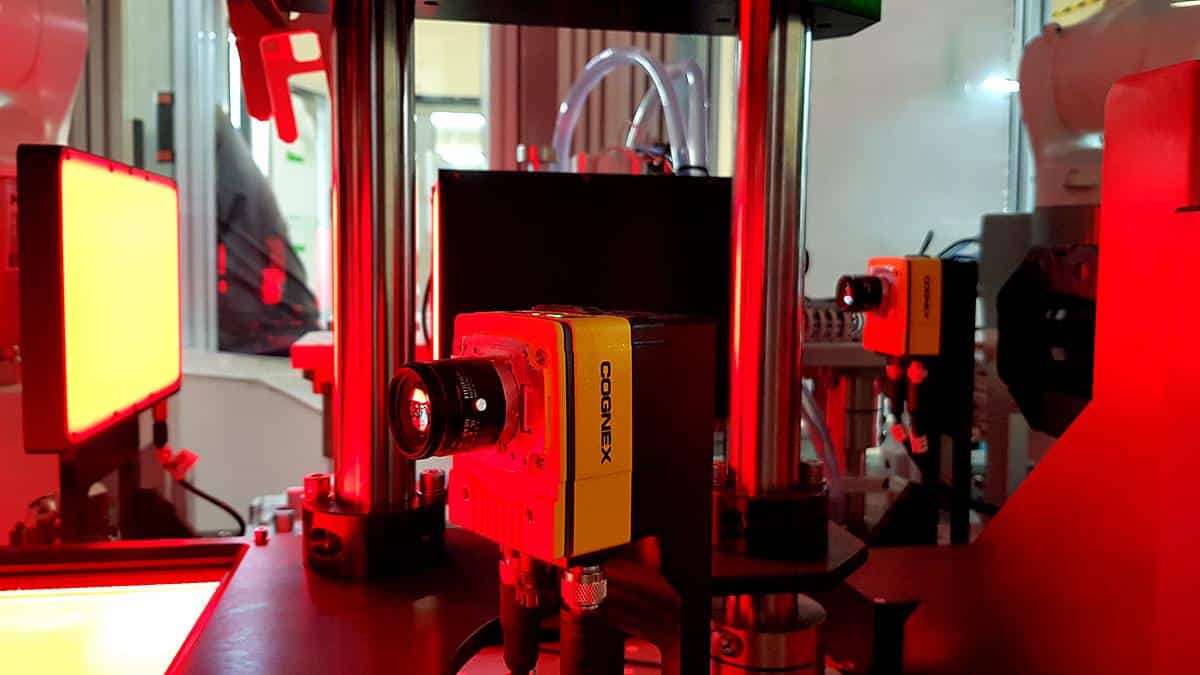

We have developed systems consisting of parts feeding hopper, bowls and tracks with a vision-guided robot ‘pick-and-place’ that operates in unison to provide a consistent, reliable supply of parts for any automation system.

Customisable

The manufacturing of a product may involve a variety of components that need a way to be fed into a system. Due to the uniqueness of each part (e.g., shape, weight, geometry, etc.), we have the experience to select the best feeding system for each component.

Product Sorting

We have expertise in presenting component parts in bulk, separated and orientated in order to be fed to a machine, we can create a seamless transition from simple part feeding through to compact feeding and testing cells.

Feed systems we have integrated include:

Vibrator Feeder

Bowls feed and orientate your products carefully while guaranteeing a consistent and accurate flow of components into your production machinery.

Coil Feeder

Feeders are used to help presses run at maximum speed with a smooth and continuous process. Software automatically matches feeder and coil unwinding speeds, together with press rate and feed length.

Flexibowl

Entire families of parts can be fed into the same system without mechanical retooling, offering constant and superior performances, even with burrs and dimensional variations.