We work across a variety of different industries and our experience in robot integration is particularly strong in the medical device, pharmaceuticals, and automotive sectors.

Some of our specialist expertise are high precision robots with lower payloads that handle smaller, more delicate parts such as lens and medical device components.

Our team are highly trained and experienced in the integration of robots across a wide variety of applications including; product transfer, assembly, testing, vision systems, high speed pick and place, simulation and end-of-arm tooling, enabling us to provide a custom solution to suit your specific requirements.

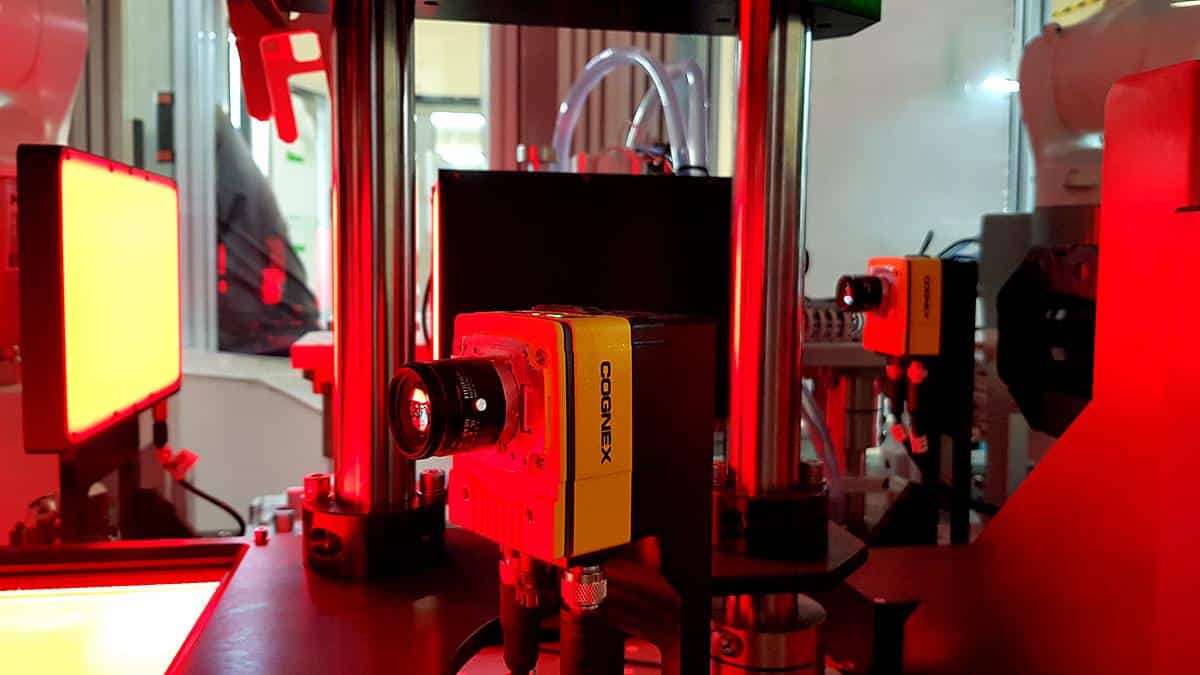

Vision Integration

Communication between multiple vision systems to align components, locate products, feedback to robots, pick products and find patterns.

Multi-platform

Integration of large (10kg) and small-scale robots (3kg) into a diverse range of projects, from standalone cells to full production lines.

End Of Arm Tooling

Designing customised EOAT equipment focused on reduced wiring & ease of service delivery to the robot arm.

Robotic systems we have integrated include:

Scara

Selective-Compliance-Articulated Robot Arms (SCARAs) are ideally suited to vertical assembly operations, such as inserting pins in holes without binding etc.

Six Axis

Six-axis robots move forward and back, up and down, and can rotate, pitch, and roll to offer more directional control than SCARAs. This is suitable for complex movements that simulate a human arm.

Delta

With 3, 4 or 6 axes, this type of high-speed assembly robots are ideal for a variety of applications. They can be installed directly into the most compact of machines and are as versatile as the human hand. They make an ideal alternative to complicated and expensive hard automation.

Cleanroom

Thanks to a special powder coating and seals to protect against particle emissions, the clean room robot features extremely smooth surfaces. Due to the avoidance of airborne particles, the robot does not generate dust or particles caused by seal abrasion, thus conforming to strict clean room criteria. Corrosion-resistant surfaces, food-compatible lubricants and stainless steel parts ensure the highest level of hygiene.

Industrial

FlexPicker® offer the fastest picking capability and has been optimised for packing applications. The robot has outstanding motion performance with the shortest cycle times, precision accuracy and high payloads.