Orthopaedic Manufacturing

PRECISION AUTOMATION

Innovation Meets Medical Excellence

Orthopaedic manufacturing operates under intense pressure to deliver life-changing products while meeting stringent regulatory requirements. These industry-specific pressures require specialised automation solutions that understand the unique requirements of medical device manufacturing.

ORTHOPAEDIC MANUFACTURING

20+ Years of Expertise

Industry Challenges in Orthopaedic Manufacturing

Manual finishing processes create ergonomic risks for operators leading to repetitive strain injuries, while inconsistent manual techniques can compromise product quality.

Environmental concerns around waste and operator exposure from blasting media, while growing market pressures demand faster turnaround times and competitive pricing.

Complex part geometries demand precision that’s difficult to achieve consistently by hand and increasing production volumes strain existing capacity.

Regulatory compliance adds another layer of complexity, requiring complete traceability throughout manufacturing processes.

OUR EXPERTISE

Proven Solutions for Complex Requirements

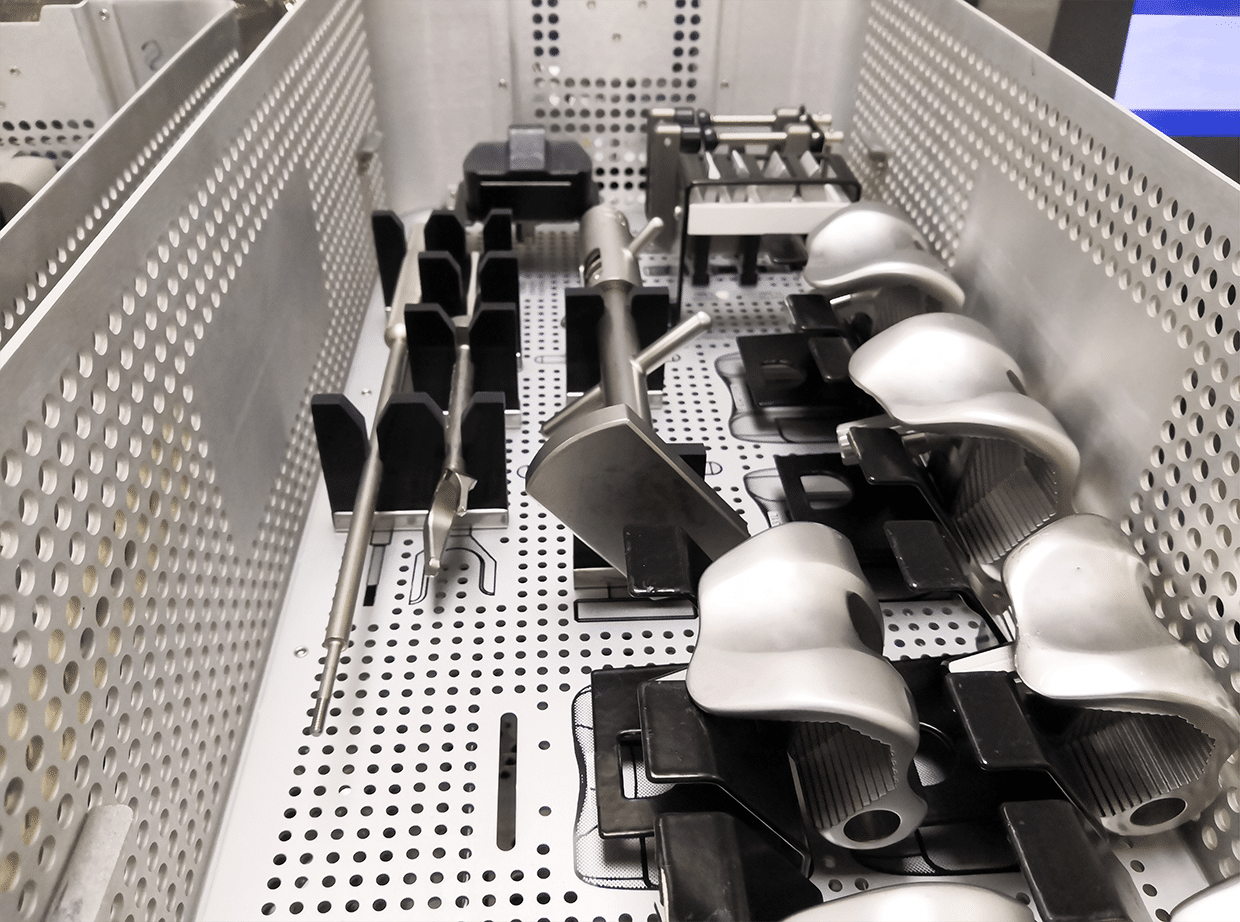

We specialise in finishing operations such as laser marking, precision blasting and grinding/polishing.

Our solutions integrate seamlessly with existing MES and ERP systems, ensuring complete traceability from raw material to finished implant. We don’t just deliver machines, we deliver validated, production-ready systems that enhance your manufacturing capabilities while maintaining the highest quality standards.

ACCREDITED COMPANY

ISO 9001:2015

VALIDATED SOLUTIONS

Ensuring compliance with the highest safety standards

We understand that orthopaedic manufacturing isn’t just about automation, it’s about:

Creating systems that meet stringent validation requirements

Maintaining clean room standards

Delivering the consistency that patient safety demands

Talk to us about your next automation project?

Get in touch with one of our automation experts.